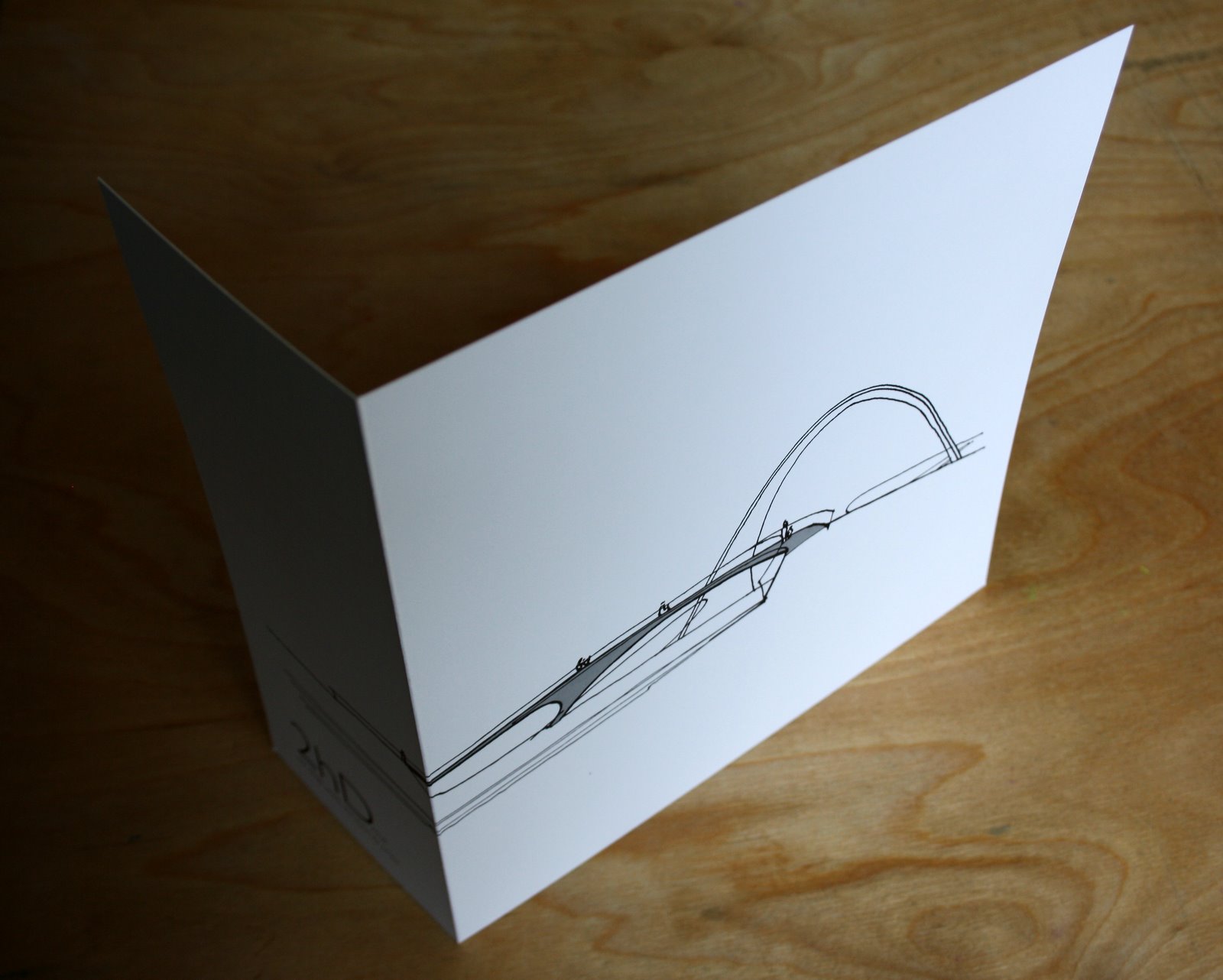

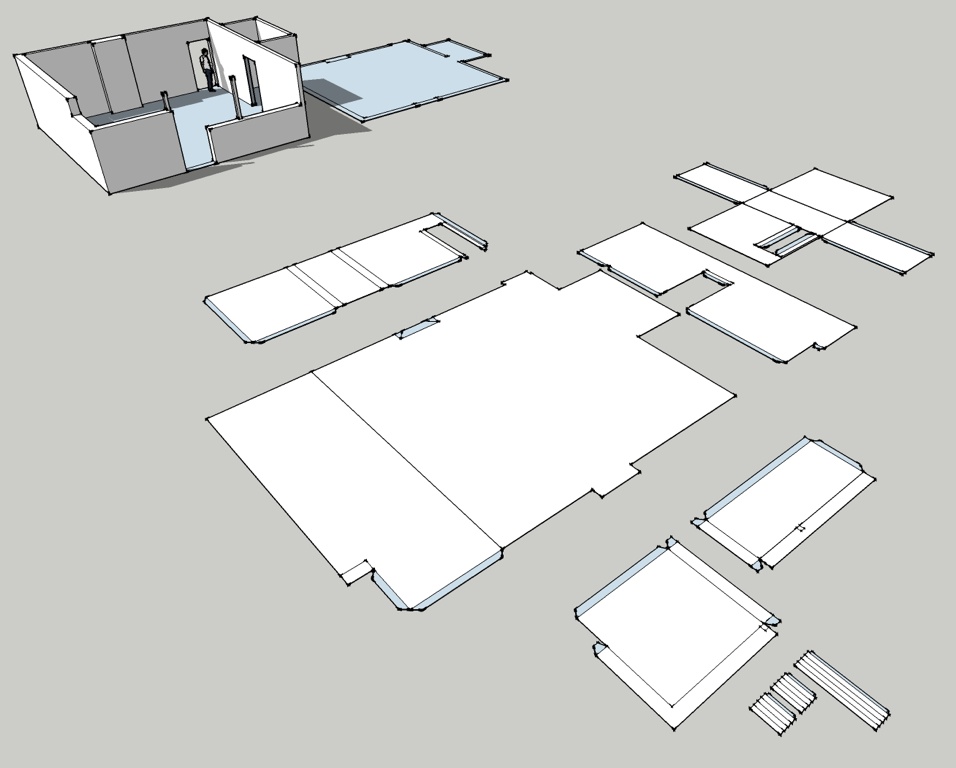

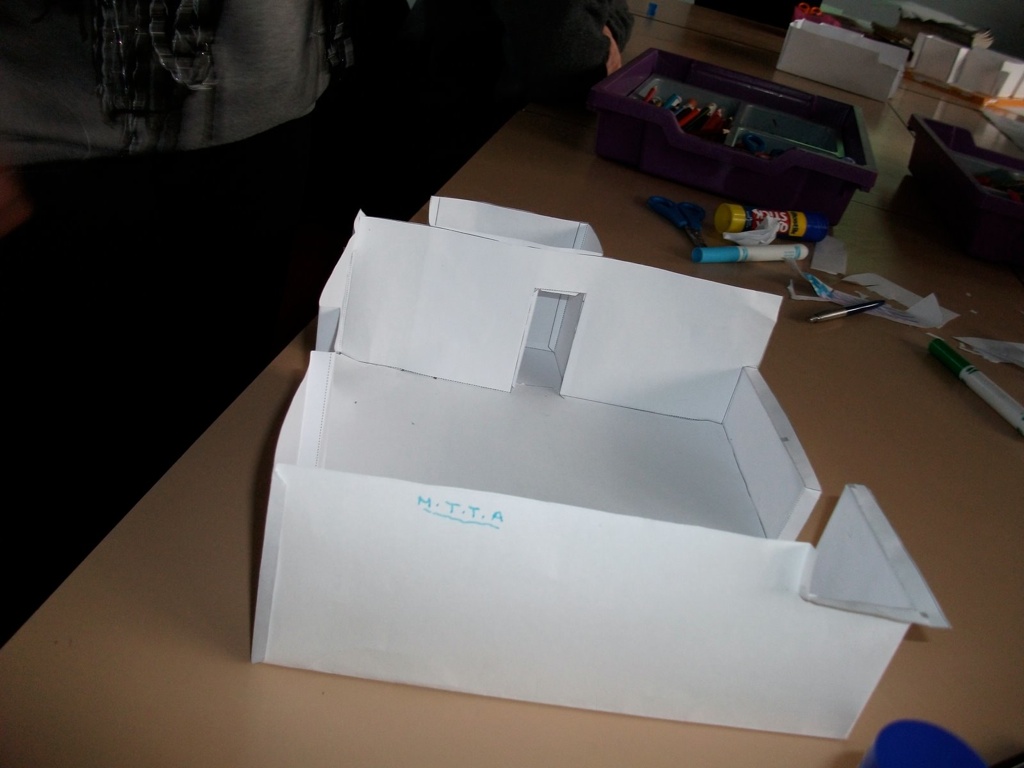

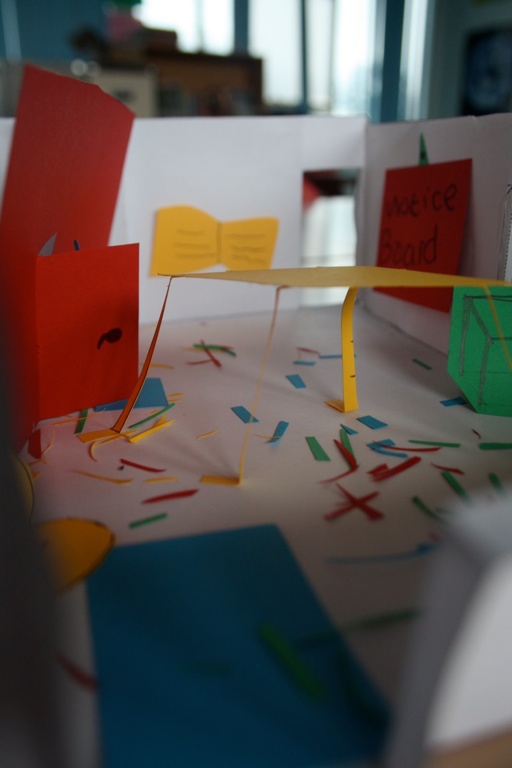

Although 3D software are essential tools at 2hD, we also love to make physical models — which have proved invaluable for communicating ideas to clients. Unfortunately, they can be time-consuming to make and we have recently missed using them as part of our design process. Could 3D printing be a solution?

I bought a Prusa MINI+ 3D printer, using a recent teaching award from Nottingham Trent University. The NTU architecture course has a real emphasis on hands-on making and craftsmanship, in conjunction with digital skills. Learning how to use the printer will bring benefits to both my practice of architecture and my teaching, allowing us to explore a range of ideas that we couldn’t before!

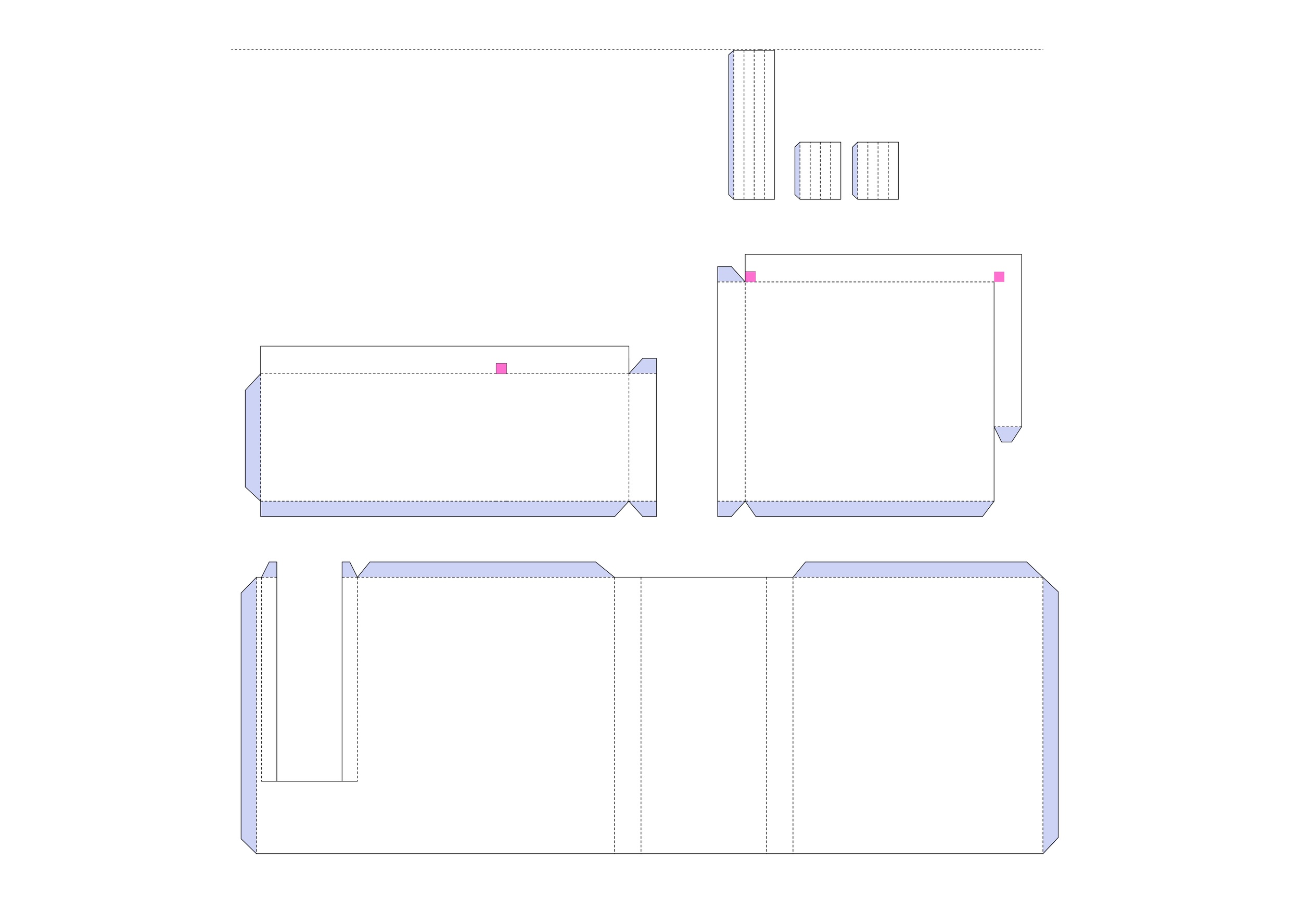

One of the Capybara trial prints…

The results of our initial trials to learn the technology were interesting, to say the least, but after a few slightly strange capybara models made for my youngest daughter, I think I was getting there!

2hD is also part of a team brought together by Tristan Hessing of Future Makers, looking into the recycling of waste plastic in design and architecture. We don’t believe in creating waste, so we are very interested in using recycled filament in our model making.

Following on from my award for innovative ideas in construction, one of the things we are considering at the moment is the 3D-printing of complex junctions in buildings. And if we can use construction industry plastic waste to create these building components, we’ll be part of a truly circular economy.